Digging deep to discover the root cause of a non-conformity is not about blaming other people, individuals or specific departments. The main point you should take from this is to learn about your organisation’s weaknesses and use procedures to reduce or remove them completely.

More importantly, it’s also a vital part of compliance with the ISO 9001 Standard. Clause 10.2 of the Standard refers to non-conformity and corrective action and requires your company to evaluate the need for actions to be taken to prevent non-conformities from reoccurring.

Clause 8.7 refers to non-conforming outputs, prompting you to create processes that stop you from delivering products or services that aren’t compliant.

Having an effective quality management system benefits your business by taking ownership of any non-conformities. To help you, we’ve created this handy guide, which will show you how to implement corrective actions that prevent the recurrence of non-conformities.

What is a non-conformance in ISO 9001?

ISO 9001 defines non-conformance as the failure to comply with the criteria outlined in a company’s quality management system (QMS). This can include customer requirements, legal regulations, and internal policies.

Non-conformance could be the result of many factors, such as defective products, ineffective processes, or employee errors. If these issues aren’t resolved, they can lead to bigger problems, such as customer dissatisfaction or fines.

For more information, see our complete guide to ISO non-conformance.

Types of non-conformance for ISO 9001

Major non-conformance

What is a major non-conformity for ISO 9001? Well, a major non-conformance is a significant issue that has a big impact on the company’s ability to meet ISO 9001 requirements. For instance, a missing quality control process that leads to unsafe products could be classified as a major non-conformance. This type of non-conformance should be addressed immediately to prevent further consequences.

Minor non-conformance

A minor non-conformance is less severe but still requires corrective action. An example might be an employee failing to follow a documented procedure on one occasion. While it may not have a direct impact on quality, it still indicates a gap in compliance that needs attention.

For more information on the differences between the two, see our blog on major vs minor ISO non-conformances.

ISO 9001 non-conformance examples

To better understand the concept, here are some examples of non-conformance in ISO 9001:

- Failure to document procedures: If a company doesn’t maintain accurate records of its processes or fails to update documentation regularly, it may be flagged for non-conformance during an audit.

- Non-compliance with safety standards: A manufacturing company might face non-conformance if it fails to ensure that all equipment meets the required safety standards, potentially putting workers at risk. See our blog on ISO 9001 for manufacturing organisations for more.

- Customer complaints: If a business receives frequent complaints about product quality or service delivery, it may highlight a non-conformance in its quality control processes.

How to handle non-conformance in ISO 9001

Identify the issue

This process begins by identifying when something doesn’t happen as expected. It could be a customer complaint about bad service, or the identification of faulty packaging during an internal inspection. These errors can be picked up in several ways, from staff logging their observations on a spreadsheet through to internal audits and management reviews.

Once spotted, it needs to be recorded in a Non-Conformity Report or Corrective Action Report. Within this report, you must identify the impact of the non-conformity and who will be affected by it.

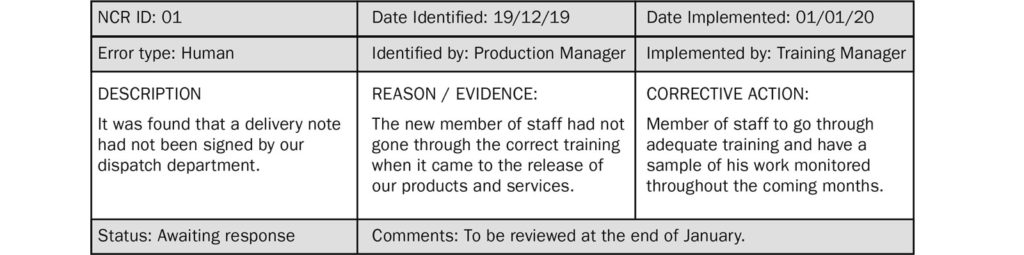

Here’s an example of a typical non-conformity log entry:

When a non-conformance has been highlighted, it’s important to focus on facts and ask yourself the following questions:

- What is the problem and what is its history?

- Where did it occur?

- When did it happen and when was it reported?

- How big is the problem, how frequent is it and how is it being measured?

Once identified you may also need to kick-start a containment process or interim response. This could range from stopping deliveries to rebooking appointments. The key is to stop the problem from reaching your customer. This will also give you time to investigate the root cause of the issue and put a more permanent corrective action in place.

Before you do, you need to be sure that this containment or interim action will stop the problem. You should therefore test the new action and review its effectiveness.

Gather a response crew

Your next step is to gather together an experienced team who can help to determine the root cause of the problem and implement corrective action appropriately. This will likely involve personnel at the top of your company, but you’l also need to include anyone who carries out the actual function.

Your team can be any size – it depends on the size and complexity of your problem. If you’re a sole trader, you may be the only member. If you do have more personnel, just be aware that a very large team can be tricky to manage.

To make your team as effective as possible, they need to have the right knowledge about the process or problem involved. You’ll also need to give them enough time and resources to complete an investigation as well as the authority to enact corrective action. A team of several people means that a team leader will be necessary too.

Your team will need to be comfortable carrying out a comparative analysis that assesses the following impact:

- What is different and unusual about the non-conformity, and what may have changed?

- How is the non-conformity linked to people, processes, machines, materials or the environment of the business?

- What are the facts surrounding the possible cause?

Finding the root cause

There are lots of different problem-solving techniques that can help you effectively resolve non-conformance. You should use the one that you’re most comfortable with. One of the best formulas is the ‘five whys’ formula. Let’s explore this in greater detail.

The ‘five whys’ formula

You don’t need any advanced maths skills to adopt this approach, but it still helps you to identify causation. It’s also suitable for sole traders or those with a team behind them.

The first ‘why’ focuses on why the problem is occurring. Start a fact-finding mission to answer this question. Don’t make an educated guess – instead use actual evidence to determine exactly what happened.

Asking this question may reveal one answer or several. For each answer, ask the question ‘why’ again. Keep doing this until you have asked a total of five ‘whys’, each one relating to the answers you have supplied to the previous question.

By this stage, an appropriate countermeasure or corrective action should be evident. If not, continue to ask ‘why’ until you can’t go any further.

Using the example from the non-conformity log, the ‘whys’ would run as follows.

- First why: A delivery note had not been signed because a member of staff had released the product without following the release and dispatch procedure.

- Second why: It was released without following the procedure because the staff member was new.

- Third why: The new staff member did this because they hadn’t had the relevant training.

- Fourth why: They did not receive the right training because there isn’t an adequate training programme in place.

- Fifth why: There isn’t adequate training because the training procedure is out of date.

Taking corrective action

Taking corrective action

Whatever problem-solving tool you’ve used, you should now have a fairly good idea of what permanent corrective action could be taken. A permanent corrective action means that it should stop the non-conformity from happening again. This means you’ll probably have to change some aspect of your processes, policies or procedures.

Before implementing, you should also consider whether there are any other opportunities for something similar to happen. You should assess the potential effectiveness of your proposed action to ensure that you really are picking the best course of action.

Once you’re confident with your choice, you can implement the permanent corrective change and remove the interim or containment action you initiated at the beginning of the process. Make sure work procedures, instructions and plans are updated to reflect the alteration and the change is communicated to the relevant people within your business too.

Monitoring and measuring

Once your corrective actions are in place, you can kick-start the monitoring and reviewing process.

This should involve the owner of each corrective action as well as your customers, if necessary.

Monitor the corrective action until it’s evident that it’s working as expected. You may want to schedule some extra internal audits to keep an eye on its effectiveness. This may be a good time to share your learning with other parts of the business too so that they can follow the same action.

The corrective action and its effectiveness should all be documented to boost your management system. Here’s an example of what evidence you can gather to support you:

- Updated procedures, plans, instructions or training

- SPC (Statistical Process Control) data

- Inspection records

- Internal audit records

- A register containing a summary of the non-conformity, the results of your analysis and your actions and decisions

Why managing non-conformance is essential

Effectively managing non-conformance is key to maintaining a robust ISO 9001 QMS. Failure to address non-conformance can lead to negative outcomes, such as customer dissatisfaction, loss of business, and potential legal implications. But, resolving non-conformance and implementing corrective actions can improve a company’s overall processes and help maintain compliance.

Managing non-conformance aligns with one of the core principles of ISO 9001 which is continuous improvement. Each time a non-conformance is identified and corrected, it supports the organisation’s ongoing growth, boosting efficiency and customer satisfaction.

Avoid non-conformance with Citation ISO Certification

We know that running a management system can be challenging for businesses while keeping up with other business demands, that’s why we’re here with the guidance, support and services you need. Speak to our ISO Consultants for advice on your non-conformance queries, or gain your ISO certification if you haven’t already.

You can get in touch with us for more support and guidance. Call us on 0333 344 3646 or email [email protected] to find out more about how we can help you stay on top of your management system.